Case Study: Complex Hot Water System Failure Investigation

Client: Private Property Owner

Location: Confidential

Services Provided:

Stage One – Initial Non-Invasive Diagnostic Survey

Stage Two – Detailed Mechanical Investigation

This ultra-high-end residential property was completed in the mid-2000s and features multiple buildings, specialist finishes, and high-value materials sourced globally.

Shortly after completion, significant leaks began appearing in several rooms across the upper floors.

The failures were severe enough to render the property uninhabitable, preventing it from being used as intended.

The client required an evidence-based, non-destructive approach to identify the root causes, confirm the extent of the failures, and develop a strategy for rectification — all while protecting the property’s finishes and minimising disruption.

Background

Stage One: Initial Non-Invasive Damp Survey

The first step was to carry out a non-intrusive survey, focusing on observation, data collection, and analysis rather than immediate opening-up works.

This initial survey involved:

Careful visual inspection of all affected rooms and service areas.

Reviewing as-built documentation and construction records.

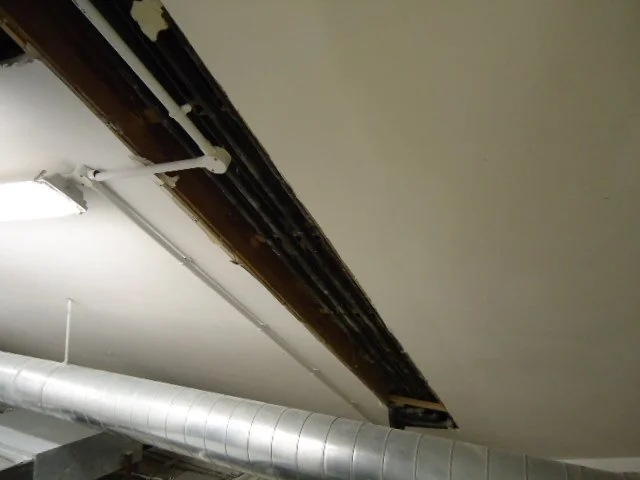

Examining accessible voids where safe to do so.

Gathering information from previous reports and investigations.

Outcome of Stage One:

We confirmed that widespread hot water system failures were likely due to a combination of material defects, poor workmanship, and design flaws.

This gave the client confidence to proceed with a more detailed investigation while avoiding unnecessary disturbance to the property at this early stage.

Stage Two: Detailed Mechanical Investigation

Following the Stage One findings, a specialist engineering review was carried out to fully assess the system.

This included:

Examination of pipework samples and laboratory testing.

Independent mechanical engineering site inspections.

Liaison with manufacturers to verify material suitability.

Assessment of boilers, valves, and associated controls.

Key discovery:

The installed pipework was made from unsuitable materials for hot water use, leading to premature failure when exposed to operational temperatures and pressures.

In addition, the boilers had been installed without adequate safety features, increasing the risk of catastrophic system failure.

The investigation revealed multiple critical issues:

Hot water pipework constructed from inappropriate materials.

Systems operating at temperatures and pressures beyond design limits.

Poor workmanship and lack of compliance with installation standards.

Boilers missing essential safety cut-offs and controls.

Ongoing risk of concealed leaks throughout the property.

Key Findings

The client received:

Independent technical evidence to support decisions and future planning.

A clear understanding of the root cause of system failures.

A step-by-step strategy to replace the entire system using appropriate materials.

A carefully considered plan to protect valuable finishes during remedial works.

By following this staged approach, the client was able to proceed with confidence, backed by reliable data and professional advice.

Final Outcome

For complex, high-value properties, a non-invasive first stage survey provides essential clarity before major works begin.

This method helps property owners:

Avoid premature or unnecessary opening-up works.

Make decisions based on independent, factual evidence.

Protect sensitive finishes while diagnosing hidden failures.

This case study demonstrates how Durndell Damp Surveys delivers structured, specialist investigations, giving clients certainty and control when faced with serious building defects.

Why This Matters